Thermal wheel

Key Information of HRW

- High heat recovery performances.

- Low investment costs.

- Less space requirements.

- Less self-consumed energy.

- Low pressure drops.

- Power for rotor drive is negligible.

- No hazard due to toxic substances in the system.

- Self-cleaning features.

- No additional filter to protect the rotary heat exchanger.

- Factory Certified performance.

Key Highlights :

Rotary Heat Exchangers with 3A molecular sieve as standard desiccant

Innovative manufacturing technology to make a double wall casing is sturdy and built for life.

Diameter Range : 500mm to 2400mm Monolithic Wheels

Wheel thickness: 200mm

Wave height : 1.7mm as standard

Ex-Factory lead time : 1 week

Description

General Principle:

AIR-TO-AIR energy recovery is the process of re-covering Heat or/and moisture between two air-streams at different Temperatures and humidity’s. This process is important in Maintaining ac-acceptable indoor air quality (IAQ) while Maintaining low energy costs and reducing overall energy Consumption Rotor systems are used for recovering the heat energy Contained in the exhaust air of ventilation systems.

The supply air is fed through one half of the continuously Rotating rotor, while the exhaust air is fed in counter-flow Through the other half of the rotor. The flow channels are Divided with supply air and exhaust air flowing in opposite Directions, whereby the warmer air flow gives off energy To the rotating heat storing mass.

In the other half of the rotor the cooler air flow meets The warm heat storing mass. Due to the temperature Difference a heat transfer takes place from the heat Storing mass to the air flow. The cold supply air is Steadily warmed as it flows through the heat storing Mass. In the other half of the rotor there is a Constant heat dissipation by the exhaust air flow To the heat storing mass. Energy savings of Up to 90 % are possible.

The second law of thermodynamics states that heat energy always transfers from a region of high temperature to one of low temperature. This law can be extended to say that mass transfer always occurs from a region of high vapor pressure to one of low vapor pressure. The ERV facilitates this transfer across a separating wall (shown by a thick horizontal line in above figure) made of a material that conducts heat and is permeable to water vapor. Moisture is transferred when there is a difference in vapor pressure between the two airstreams.

Product Description :

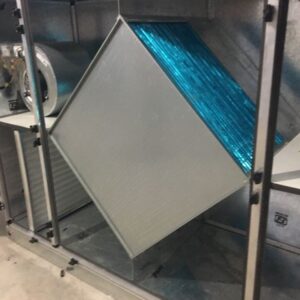

General Information – The rotary heat exchanger consists of a rotating wheel, casing and drive unit. As the wheel rotates slowly, the heat from the exhaust air is picked up by the aluminium in the matrix and transferred to the cool supply air. Rotary heat exchangers are often the preferred choice and the high sensible efficiency that they provide. The possibility of adding coating to the wheel, which allows latent transfer, is another factor favoring these products

Matrix Material –

- Aluminium (Condensation)

- Silica Gel Coated (Adsorption)

- Molecular Sieve Coated (Adsorption

- Wave Height

- Wheel Construction

- Corrosion Resistant Shaft

- Casing

- Covered Casing

- Inspection Hatches

Reviews

There are no reviews yet.